|

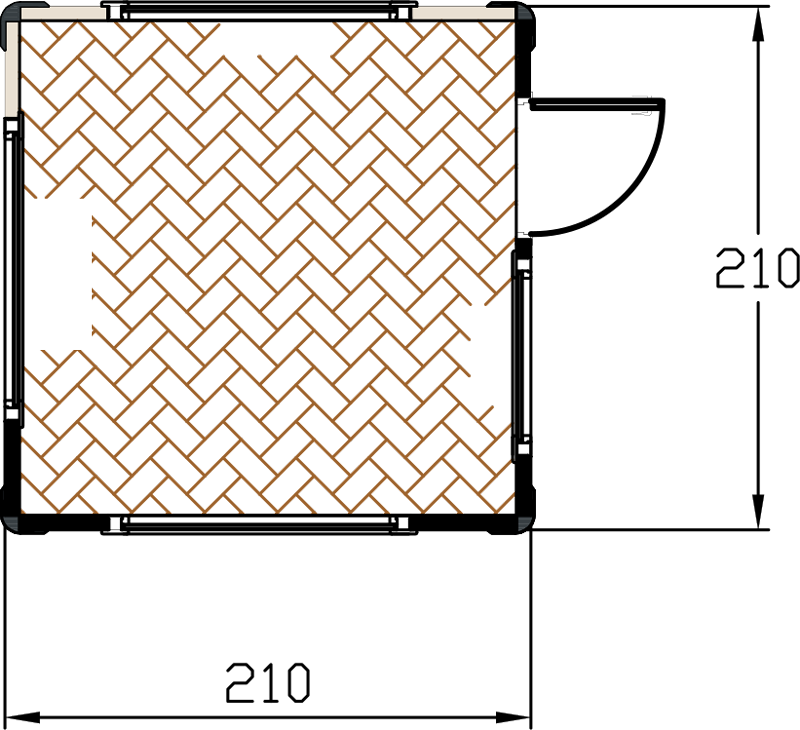

KARMOD PANEL CABIN TECHNICAL SPECIFICATIONS (ANNEX-A)

|

| TECHNICAL DATA |

| Earthquake Conditions |

1st degree |

| Metal Materials |

ST 37 GALVANIZED METAL PROFILE |

| Climate Conditions |

Turkiye Climate Regions |

| Snow Load |

80 Kg/m² |

| Insulation |

TS 365 NEW GENERATION FLAMMABLE B1 CLASS Polystyrene Foam (EPS)

|

| Wind speed |

80 Km/Hour (Fixing to the ground is the responsibility of the customer |

| Chassis Load Capacity |

200 Kg/m²

|

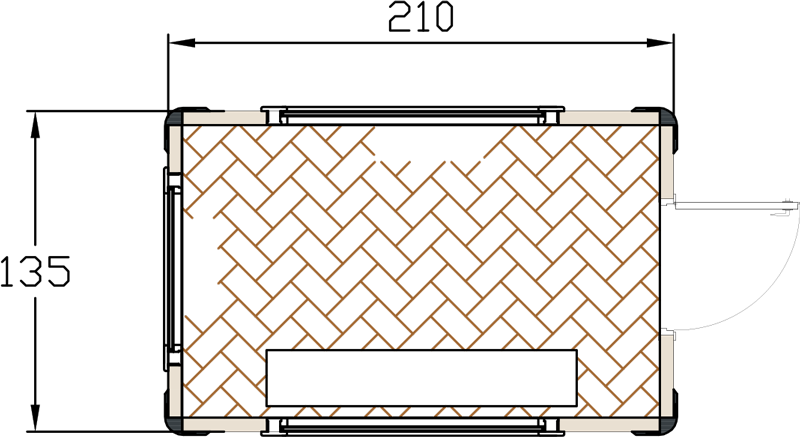

| FLOOR |

| System |

The floor of the cabin is made of specially shaped steel construction and 20*40-30*50 one-piece box profiles. The ground to be placed must be level. |

| Floor covering |

Fibercement, cemented particle board or equivalent board plate is used as the floor covering of the cabin. |

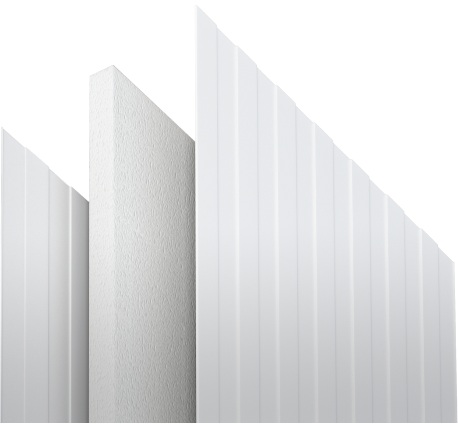

| EXTERIOR PANEL |

| Exterior Panel Cladding |

External surface coatings RAL 9002 ELECTROSTATIC PAINTED SHEET. |

| Inner Panel |

Internal surface coatings RAL 9002 ELECTROSTATIC PAINTED SHEET. |

| Panel Insulation |

Polystyrene Foam (EPS) with 30 mm thickness and 16 kg/m³ density is used. The fire class is B1. It does not smell and mold. It provides heat and sound insulation. |

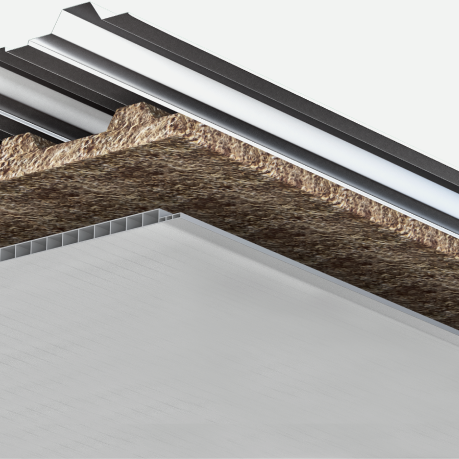

| ROOF |

| Roof System |

It is manufactured from ABS material with a single wall of 4 mm thickness. The specially prepared 1.5 mm steel profile, reinforced with galvanized chassis carcass, is mounted to the cabin construction with screw connection. |

| Roof Insulation |

In the roof construction, insulation with 40 mm thick and 16 kg/m³ density Polystyrene Foam (EPS) and perfect impermeability are provided with a special form GRP roof. |

| Inner Surface Coating |

PVC Paneling is used as ceiling covering. |

| Exterior Surface Coating |

It is a 0.40 mm electrostatic powder coated galvanized sheet material resistant to the external atmosphere and the ultraviolet rays of the sun. It has anticorrosive, washable, rustproof and rotproof properties. Body painting in different colors is not allowed. |

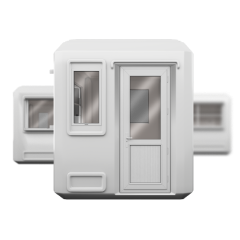

| DOORS |

| Exterior Door |

It is a white colored special hinged PVC door. TSE certified locks and special door handles are used. The outer door size is 71.5 x 184.5 and the upper part is 4 mm thick door glass, the outer surface of the under-door mirror is 0.40 mm Ral 9002 painted micro-rolled galvanized sheet and the inner surface is paneled. |

| WINDOWS |

| Window |

It consists of electrostatic powder coated white aluminium profile frames. |

| Glass |

The windows of the cabin are made of 4 mm thick tempered glass (auto glass). It is produced in a way that does not harm people when the glass is broken. |

| PAINTS |

| Metal Parts |

2 mm thick steel profile galvanized chassis is used. The construction is not painted. |

| Galvanized material outer cover parts are produced in electrostatic painted standard colors upon request. |

| ELECTRICAL INSTALLATION |

| Cable |

3 x 2.5 TSE certified NYM brand cable was laid on the surface using the electrical wiring duct. |

| Fuses |

16 A TSE certified fuse automat is used. |

| Lighting Fixture |

TSE certified donut or globe lighting fixtures are used. |

| Sockets and Switches |

2000 W 220 Volt resistant TSE certified materials are used in electrical switches and grounded sockets. |

| SANITARY INSTALLATION (Surface mounted) |

| Sanitary ware |

TSE certified materials are used. |

| Clean Water Installation |

TSE certified PPRC materials are used. |

| Waste Water Installation |

TSE certified PVC material is used. |

| EXTERNAL CONNECTIONS |

| It is the customer's responsibility to pour concrete 20 cm more than the cabin dimensions, install the cabin on the ground, and make electricity, clean water and waste water connections. |

| OPTIONAL ACCESSORIES |

| Optionally, special requests such as window eaves, counters, tables, shelves, sinks, blinds, interior wall partitions and additional WC are made for a fee. |

| LIFTING SYSTEM and SHIPMENT |

| Depending on the conditions of the area to be shipped, it is possible to load with a crane thanks to the eyebolt rings in the inner corners. However, for this, equal steel rope and a minimum of 2 m. Pay attention to the boom distance. In cases where it is not possible to load with a crane, there are feet that allow transportation from the bottom with forklift or pallet truck. The vehicle should approach as far as the cabin will be lowered. |

| Karmod Cabin Technologies reserves the right to make changes to technical specifications. |