|

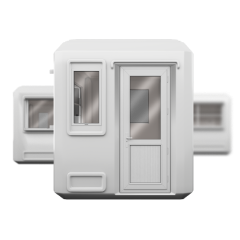

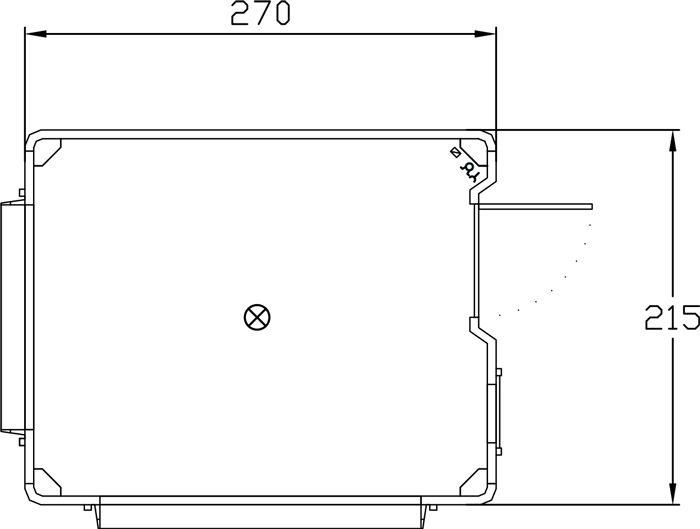

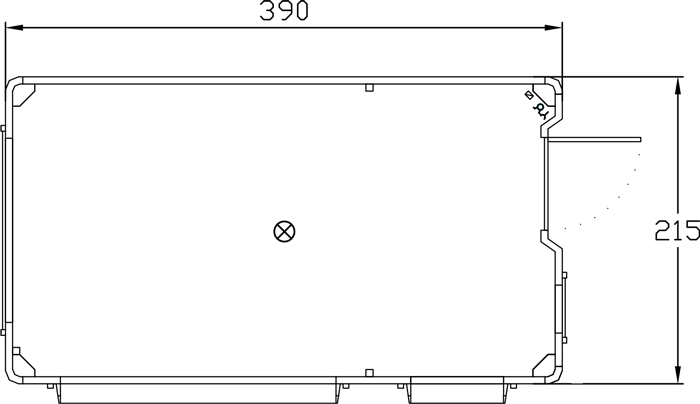

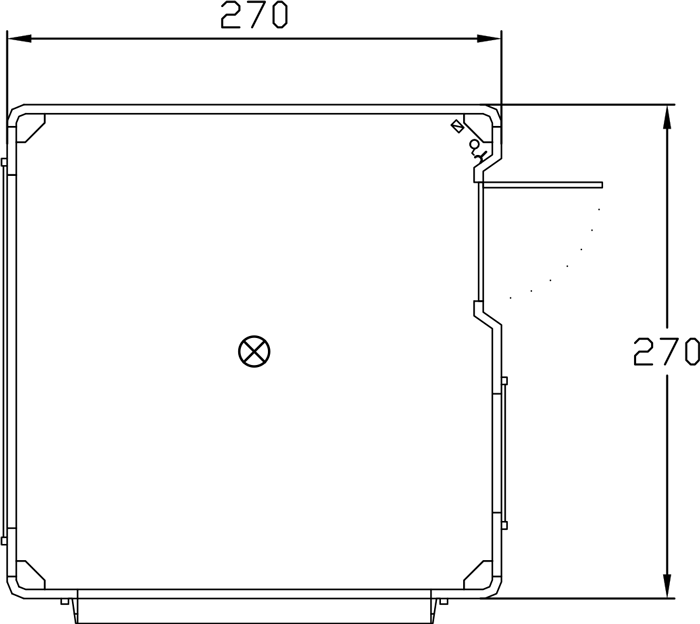

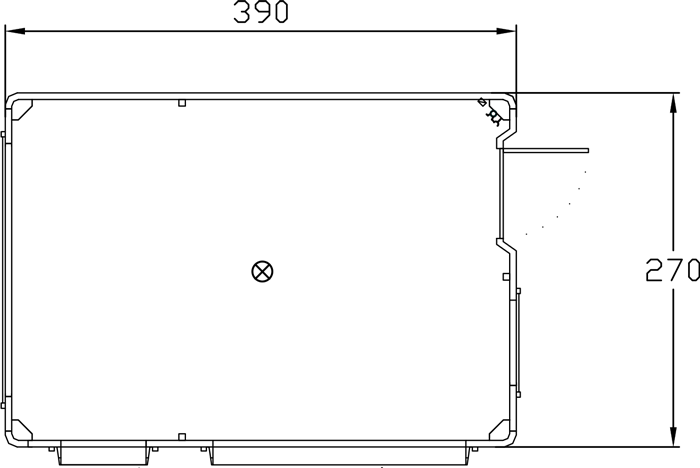

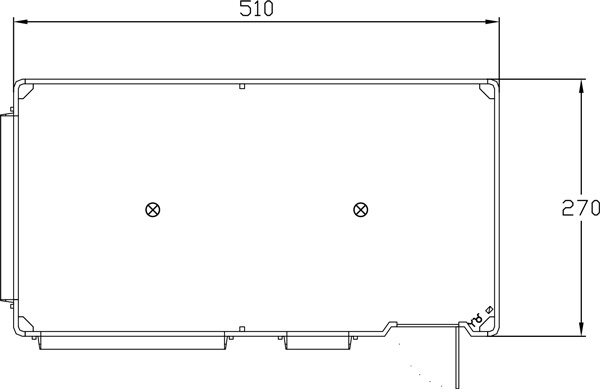

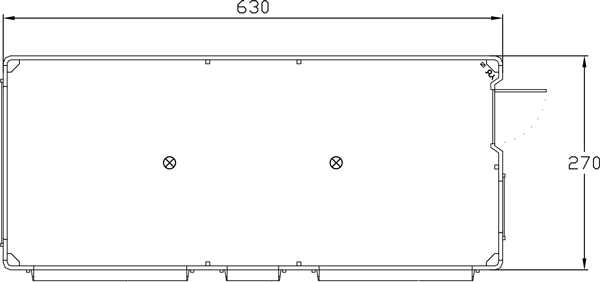

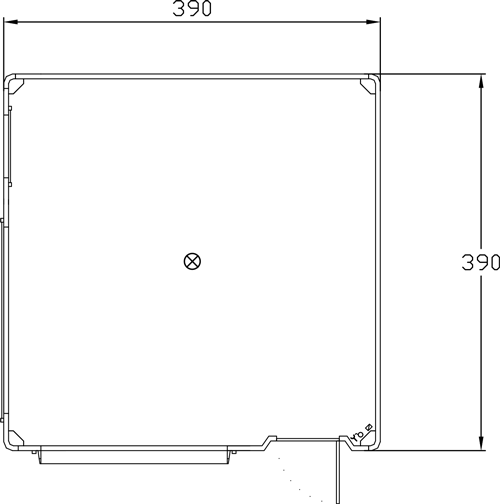

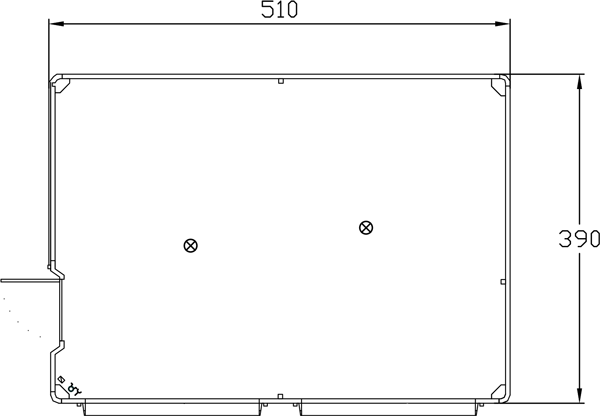

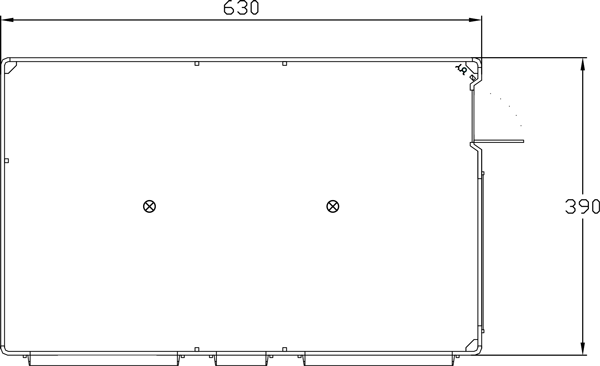

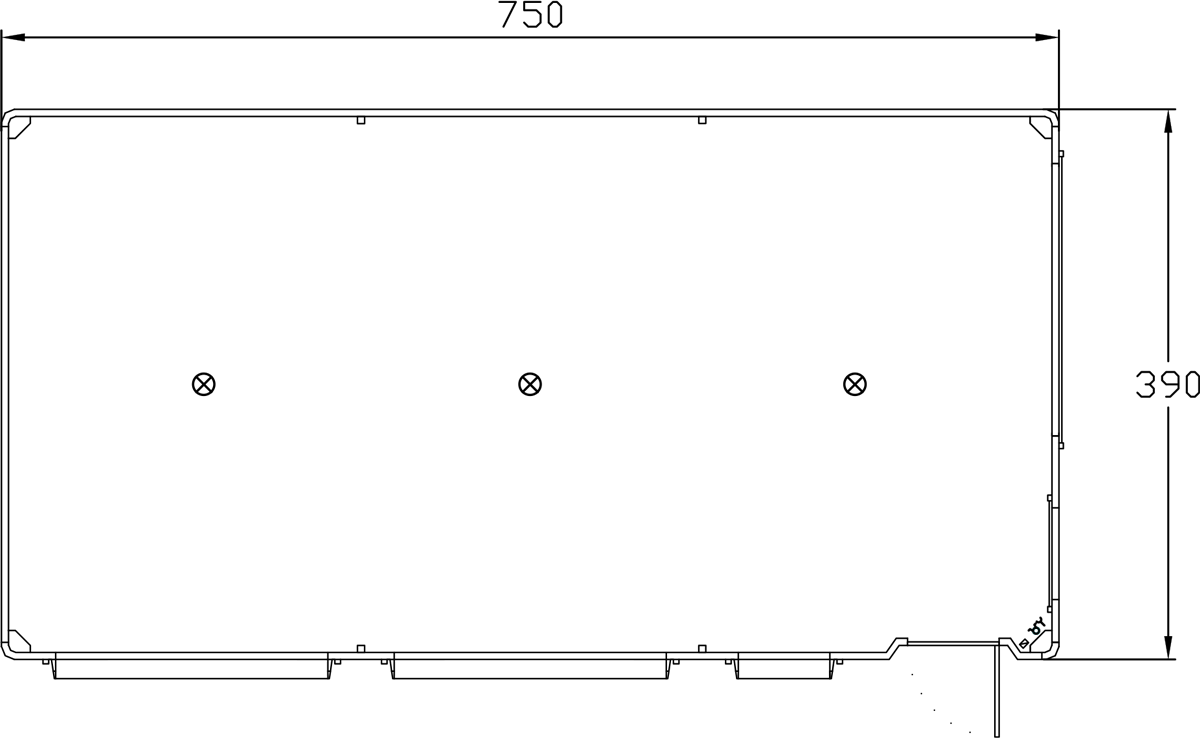

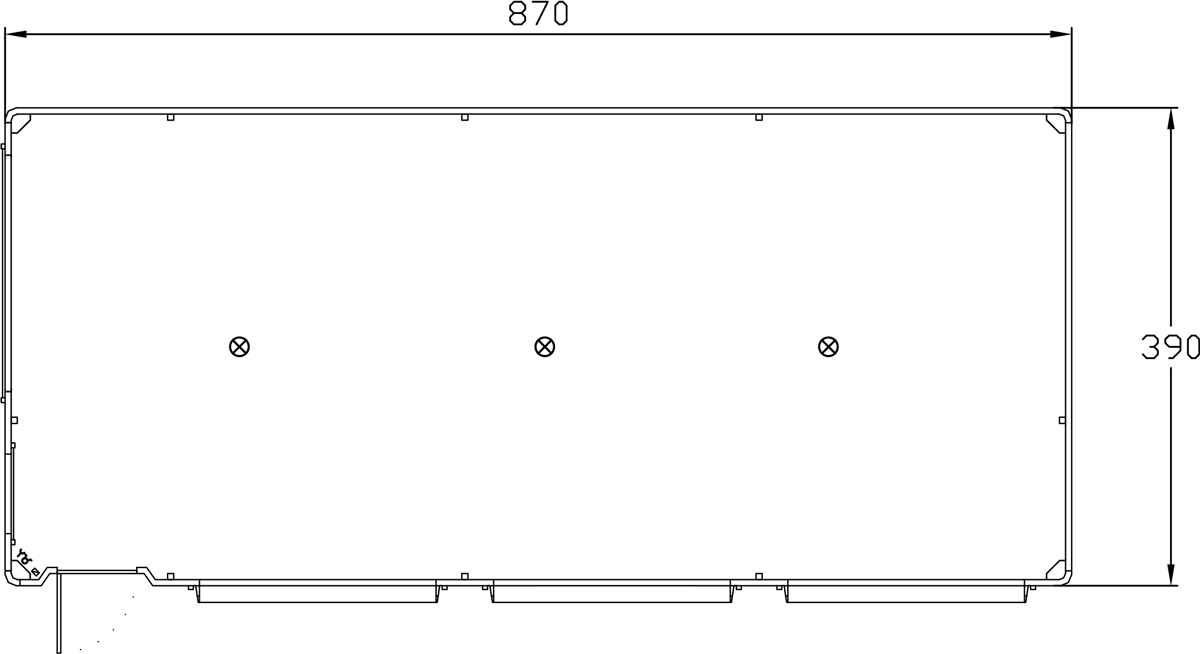

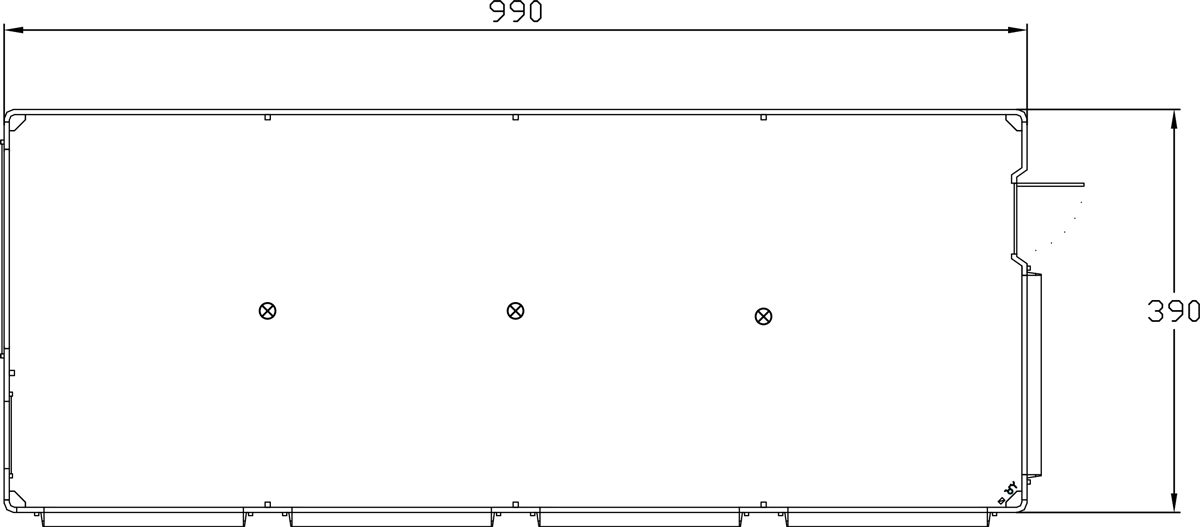

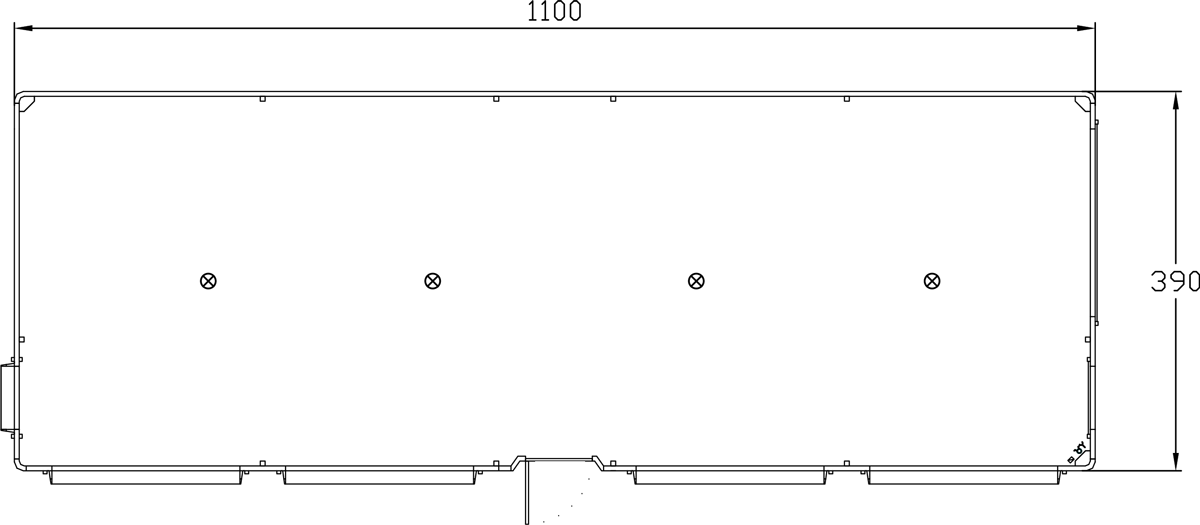

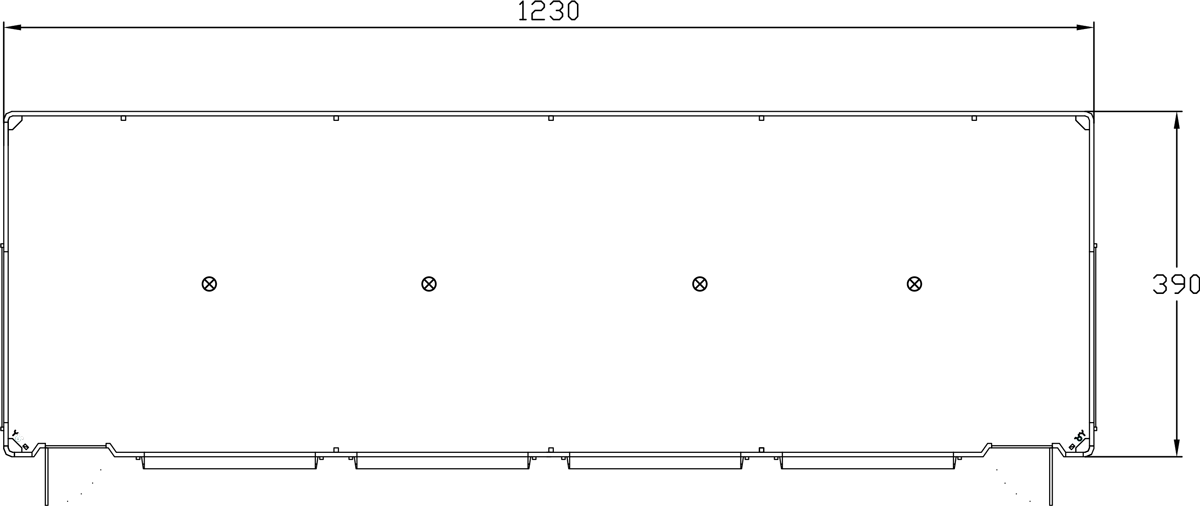

KARMOD CPT CABIN TECHNICAL SPECIFICATIONS

|

| TECHNICAL DATA |

| Earthquake Conditions |

1st degree |

| Metal Materials |

ST 37 GALVANIZED METAL PROFILE |

| Climate Conditions |

Turkiye Climate Regions |

| Sound insulation |

TS EN ISO 11957:2010;TS EN ISO 717-1:2013 ( Dp,W= 13 Db) |

| Snow Load |

80 Kg/m² |

| Insulation |

TS EN 13165 POLYURETHANE FOAM (PU)-FLAMMABILITY CLASS “B” |

| Wind speed |

79 Km/Hour (Fixing to the ground is the customer's responsibility |

| Thermal Conductivity |

TS EN ISO 8990: Heat permeability Coefficient (Ust) W/ (m²*K) 0.591 |

| Chassis Load Capacity |

200 Kg/m²

|

| FLOOR |

| System |

The chassis of the cabin is produced from special welded carrier profiles. The cabin is mounted on this chassis. The floor on which the cabin will be placed must be levelled. |

| Stabilization against Wind Speed |

Fixing to the ground in the wind is optional. It is given upon request from the customer. |

| Floor covering |

As the floor covering of the cabin, the floor covering flames surface is covered with 2 mm PVC floor covering. |

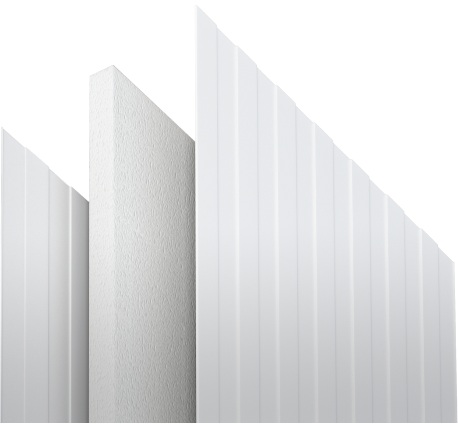

| EXTERIOR PANEL |

| Mold System |

It is produced by pressing in specially shaped metal steel construction and polyester molds, with the only automation technology in Turkiye and in the world, with a baking system at 50 degrees (CTP) and by removing the solvent gas in the gelcoat sandwich panel. |

| Cabin Production System |

Glass fiber reinforced (CPT) polyester and gelcoat materials are manufactured as double-walled polyurethane sandwich panel with the technique of curing at 50 degrees with a baking system. Specially shaped panels, with their modular structure, after screwing and mounting, are isolated by using antibacterial neutral silicone and are hygienic and long-lasting with protection against water, snow, dust, pests and bacteria. |

| Exterior Surface Coating |

It is anticorrosive, washable, rustproof and rot-proof by using polyester-based off-white (fluorescent) color isophthalic acrylic-based special gelcoat that is resistant to the external atmosphere and the ultraviolet rays of the sun. |

| Inner Surface Coating |

It is anticorrosive, washable, rustproof and rot-proof by using polyester-based off-white (fluorescent) color isophthalic acrylic-based special gelcoat that is resistant to the external atmosphere and the ultraviolet rays of the sun. |

| Wall Panel Insulation |

It is produced by injecting polyurethane foam with 30 ̴ 35 mm thickness, 42 density Italian origin 140 bar high pressure machines. |

| INTERIOR PANEL |

| System |

It is formed by injecting CPT (glass fiber reinforced polyester) and rigid polyurethane foam and producing specially shaped panels. |

| Inner Surface Coating |

A CPT coated composite panel was formed with a special glossy off-white (fluorescent) color gelcoat with isophthalic acrylic. |

| Wall Insulation |

Panels produced in our facilities by injecting 42 density polyurethane with high-pressure machines and using new generation polyurethane provide high heat and sound insulation. |

| GENERAL PANEL FEATURES |

| The special wall panels that make up Karmod cabins are manufactured using neolu off-white (fluorescent) gelcoat material, the inner and outer surfaces of which are resistant to the ultraviolet rays of the sun at 60 degrees and the cold of -50 degrees. Due to the nature of the material used, there is a tolerance of ± 2% in the dimensions of the product. The outer and inner panels have atmospheric conditions and anticorrosive properties. It is washable, rustproof, rotproof and easy to clean. |

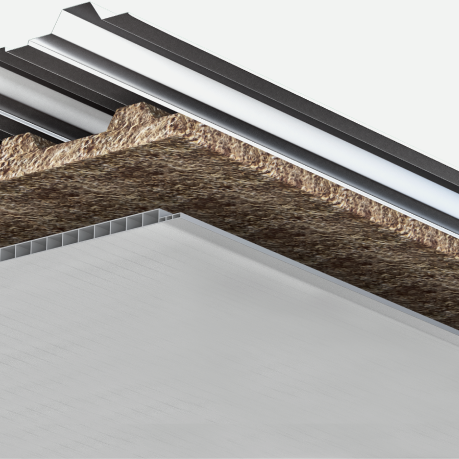

| ROOF |

| Roof System |

It is manufactured from glass fiber reinforced (CPT) polyester material as a double-walled polyurethane sandwich panel. Specially shaped roof panels are attached to the wall panels with mounting screws, and then isolated with antibacterial silicone, providing protection against water, snow, dust and bacteria, providing a hygienic appearance. |

| Roof Insulation |

The CPT composite panel is obtained by injecting 42 density polyurethane foam to our roof panels. |

| Inner Surface Coating |

Polyester-based, off-white (fluorescent) color isophthalic acrylic-based special gelcoat is used, which is resistant to the external atmosphere and the ultraviolet rays of the sun. |

| Exterior Surface Coating |

Polyester-based, off-white (fluorescent) color isophthalic acrylic-based special gelcoat is used, which is resistant to the external atmosphere and the ultraviolet rays of the sun. |

| DOORS |

| Exterior Door |

It is a white colored PVC door with 4 special hinges. Espagnolette locked. The size of the outer door is 71.5 x 184.5, the upper part of which is 4 mm thick door glass, and the bottom of the door is covered with PVC panelling. For colored cabins, the door color will be white unless requested by the customer. |

| WINDOWS |

| Window |

It consists of electrostatic powder coated white aluminium profile frames. In colored cabins, the color of the joinery will be white unless requested by the customer. |

| Glass |

4 mm thick tempered glass (auto glass) is used in the window glasses of the cabin. It does not harm the user when the glass is broken. |

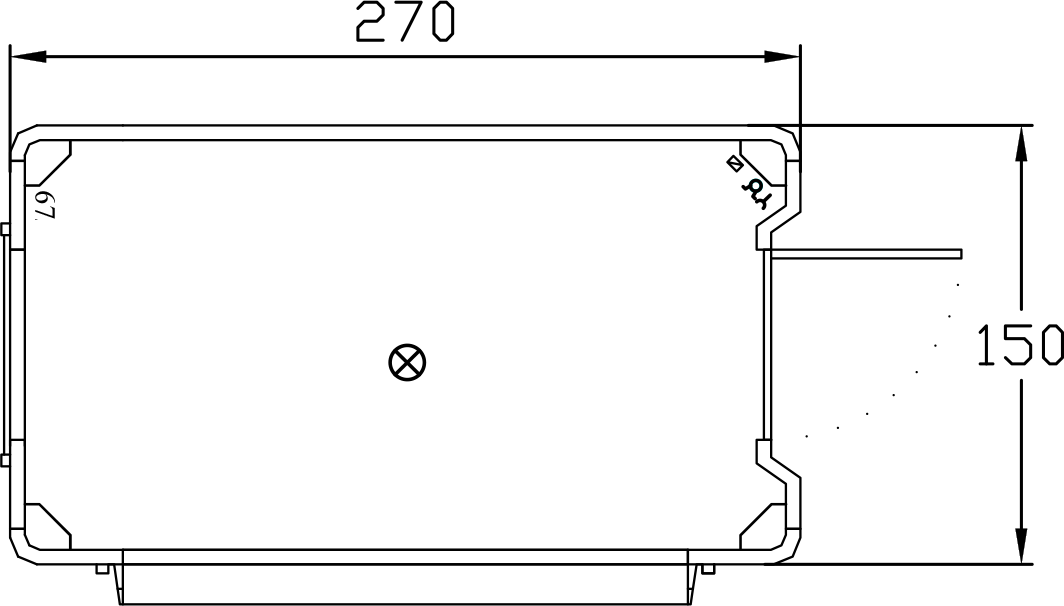

| PAINTS |

| Metal Accessories |

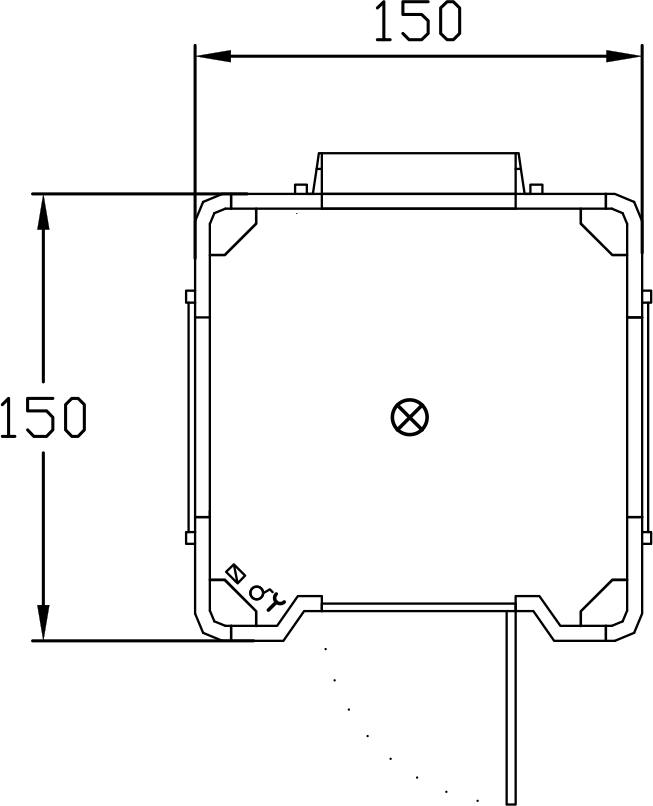

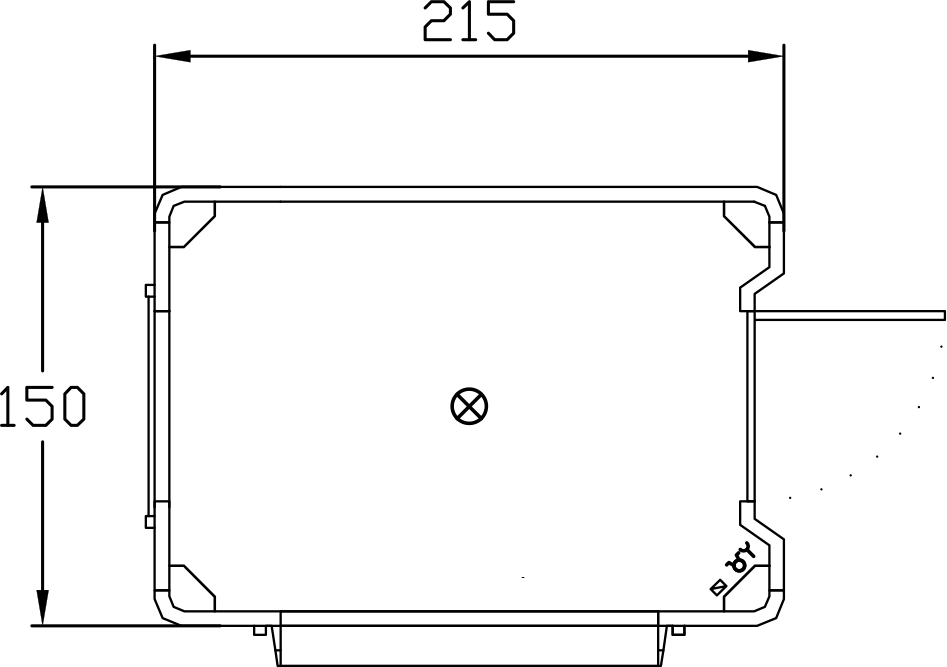

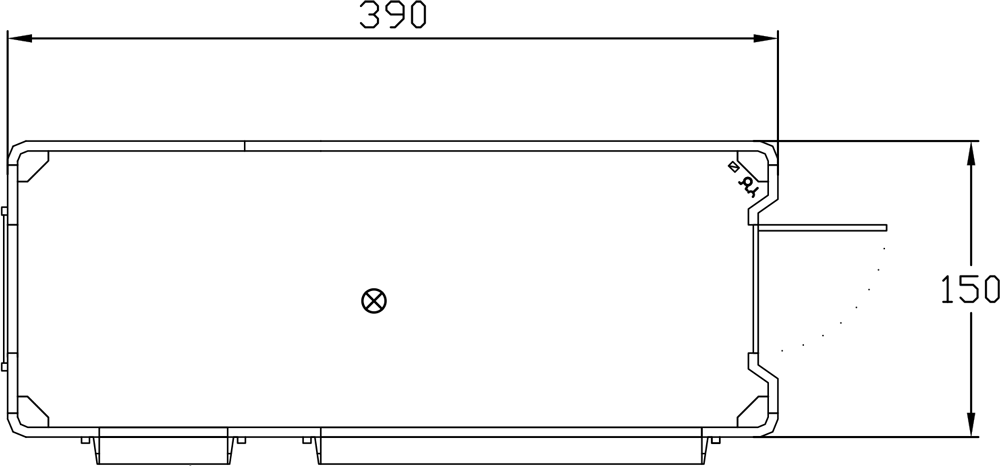

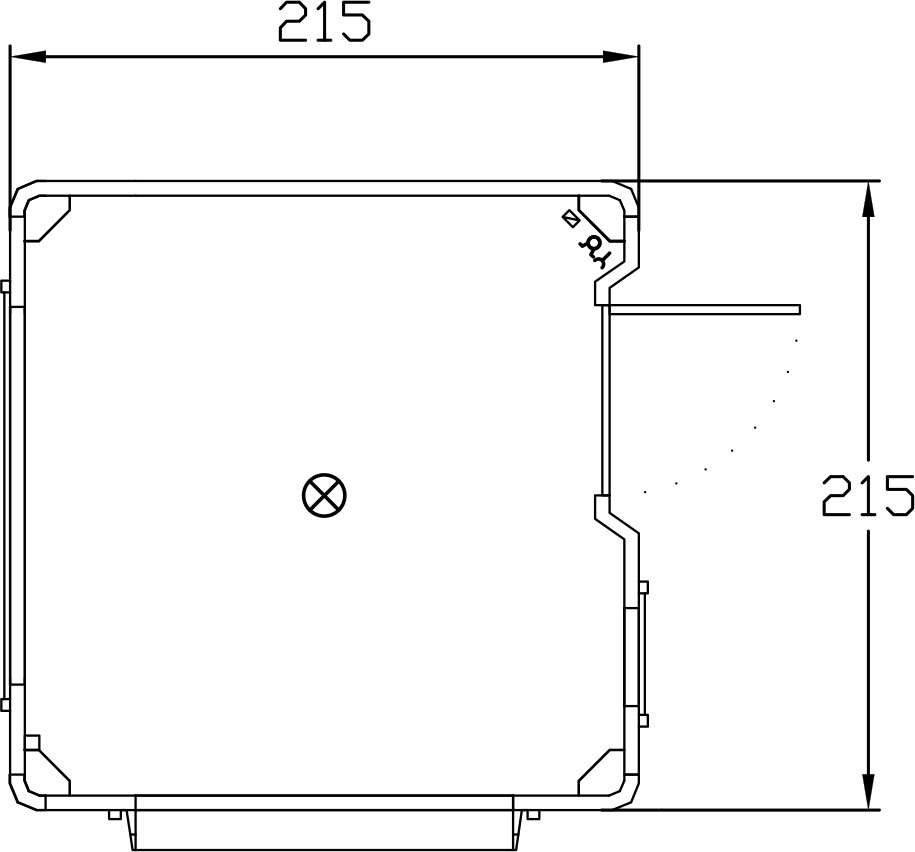

1.5 mm thick steel profile galvanized chassis is used from 150*150 size to 270*270 size. |

| After 270*270 size and all WC chassis are profile, 1 coat of Rapid primer paint is applied on them. |

| ELECTRICAL INSTALLATION |

| Cable |

1 x 2,5mm and 1x1,5 mm TSE certified NYM cable was installed on the inner corner closure. Electric switch and 2000W 220v resistant grounded sockets are installed. Telephone socket is optional, if the customer requests it can be installed. |

| Fuses |

16 A TSE certified fuse automat is used. |

| Lighting Fixture |

TSE certified globes are used, whose senses are increased according to the cabin dimensions. |

| Sockets and Switches |

TSE certified sockets and switches are used. Telephone socket is optional. |

| SANITARY INSTALLATION (Surface mounted) |

| Sanitary ware |

TSE certified sanitary ware materials are used. |

| Clean Water Pipes |

TSE certified PPRC clean water pipes are used. |

| Waste Water Pipes |

TSE certified PVC waste water pipes are used. |

| OPTIONAL ACCESSORIES |

| Optional accessories such as counters, tables, shelves, sinks, blinds, ventilation fan, interior wall partition and additional WC are available for a fee. |

| SHIPMENT |

| Forklift can be used for cabin unloading and loading. The blades of the forklift must be long. Short blades will damage the cabin floor. Optionally, chassis with forklift pockets can be made. Large cabins should be transported with the help of a crane by connecting them from the bottom with a sling. For carrying with a sling, slinging lugs can be made optionally on the lower chassis. When loading or unloading with a sling, the load crossmember must be transported in accordance with the instructions so that the sling does not compress the panel. |

| Karmod Cabin Technology has the right to make changes in the technical specifications. |