From the freezing winters of the Midwest to the scorching heat of the Southwest, U.S. weather conditions test the limits of every building material. For companies relying on modular structures, selecting the right cabin type can make or break long-term performance. The two most common options—Panel Cabins and GRP (Glass Reinforced Plastic) Cabins—offer different strengths in durability, insulation, and maintenance. But which performs better when exposed to America’s toughest climates?

This guide compares the two head-to-head, helping contractors, industrial operators, and facility managers make informed, cost-efficient decisions.

Understanding Panel Cabins: Materials and Strengths

Panel cabins, often constructed with steel frames and insulated sandwich panels, are renowned for their balance between strength, affordability, and versatility. Their core—typically polyurethane or polystyrene—offers excellent thermal insulation, keeping interiors comfortable in both hot and cold weather.

Panel systems are also modular, allowing for quick installation and easy scalability. The Sandwich Panel Cabin design, for instance, provides high structural integrity while minimizing heat transfer and condensation.

In U.S. regions like Texas, Arizona, or Nevada, where temperature fluctuations are intense, panel cabins excel by maintaining interior comfort and reducing energy consumption.

Exploring GRP Cabins: Design and Durability

GRP (Glass Reinforced Plastic) cabins—sometimes referred to as fiberglass-reinforced structures—are built from composite materials that combine lightweight design with impressive strength and corrosion resistance. Unlike metal-based systems, GRP cabins are not susceptible to rust, making them ideal for coastal and humid climates.

The GRP Kiosk Modular Cabin series is a great example of this engineering. Its one-piece molded construction ensures water resistance, long service life, and minimal maintenance. These features make GRP cabins especially valuable for security posts, utility enclosures, or industrial zones that experience frequent rainfall or salt-laden air.

Because GRP materials do not corrode or warp, they deliver unmatched longevity even in environments that would degrade traditional steel structures.

Weather Performance: Heat, Cold, and Humidity Resistance

When it comes to handling extreme temperatures and moisture, both cabin types offer unique advantages.

- Heat Resistance: Sandwich panel systems used in panel cabins reflect sunlight efficiently, keeping interior temperatures stable in high heat zones. GRP cabins, while slightly less insulative, resist UV degradation exceptionally well.

- Cold Weather: Panel cabins with thick insulation cores retain heat more effectively, reducing reliance on HVAC systems in northern states.

- Humidity and Corrosion: GRP cabins dominate in humid or coastal areas—such as Florida or Louisiana—where salt exposure can deteriorate metal surfaces.

The best performance depends on matching the cabin type to the environment: panel cabins for insulation-driven needs, GRP cabins for high-humidity and corrosion-prone regions.

Maintenance and Longevity Comparison

Durability isn’t just about strength; it’s about the cost and effort required to maintain that strength over time.

Panel cabins require periodic checks on sealants, joints, and external coatings, particularly in areas with heavy precipitation or snow. However, maintenance is relatively simple and inexpensive.

GRP cabins, on the other hand, require almost no maintenance. Their smooth, non-porous surfaces resist dirt buildup and can be cleaned easily with water. Because they’re monolithic (single-piece), there are no seams or joints where leaks can form—an important feature in hurricane or storm-prone regions.

For long-term ROI, both materials perform well, but GRP’s minimal upkeep can be a decisive advantage for operators who prioritize hands-free maintenance.

Cost Efficiency and ROI Considerations

Panel cabins are generally more affordable upfront, especially for large-scale projects requiring multiple units. Their modular sandwich panel design allows for mass production, fast delivery, and easy repair if damaged.

GRP cabins, while slightly more expensive at the outset, often pay off in the long run through reduced maintenance and longer service life. When factoring in total ownership cost over 10–15 years, GRP models can be more economical in regions with high humidity or chemical exposure.

Karmod Cabin offers both solutions, enabling customers to tailor their choice based on geography, budget, and usage type. Whether it’s a temporary office or a long-term installation, the company’s engineering expertise ensures maximum efficiency and reliability.

Safety and Structural Integrity

Regardless of the chosen material, safety remains a top priority for industrial and construction applications. Both cabin types can be integrated with advanced safety features like reinforced frames, fire-resistant panels, and secure locking systems.

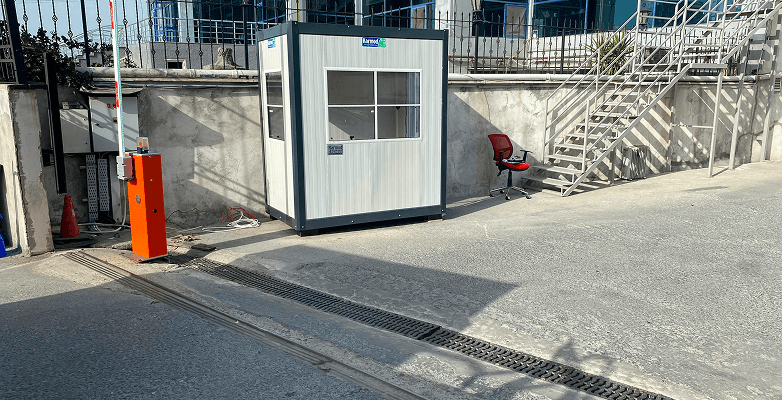

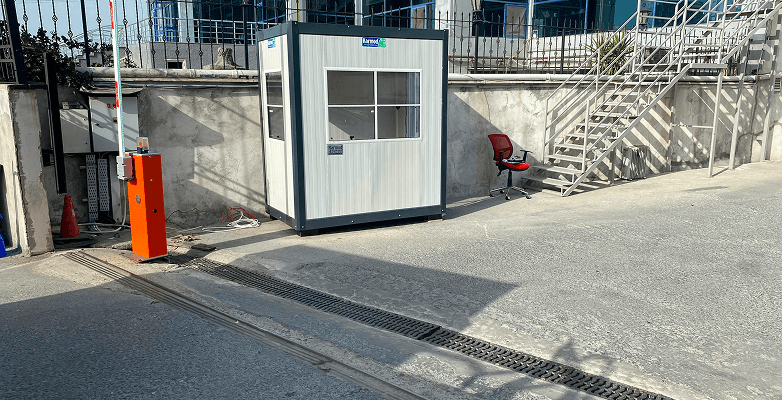

For high-risk or security-critical sites, hybrid designs—combining GRP exteriors with panel-insulated cores—offer the best of both worlds: impact resistance, insulation, and low maintenance. Modular setups like the Safety Cabin showcase how adaptable designs can meet both comfort and compliance requirements in demanding environments.

Why Karmod Cabin Excels in Harsh Climates

Karmod Cabin stands out as a trusted global manufacturer specializing in modular and prefabricated cabin systems that meet international performance standards. Their product portfolio includes GRP, sandwich panel, and hybrid solutions—each tested against diverse climatic conditions.

In the U.S. market, Karmod Cabin’s commitment to quality means clients can rely on cabins engineered to resist extreme heat, cold, and humidity without sacrificing visual appeal or comfort. From remote job sites to urban facilities, the company’s modular technology ensures resilience and operational efficiency year-round.

When selecting between Panel and GRP cabins, there’s no one-size-fits-all answer. The decision depends on local weather, operational needs, and budget priorities:

- Choose Panel Cabins if insulation, energy efficiency, and modular scalability are top priorities.

- Choose GRP Cabins if corrosion resistance, waterproofing, and long-term durability are critical.

For organizations seeking expert guidance, proven engineering, and weather-tested modular structures, one name consistently delivers confidence and quality worldwide.