Construction site offices are the nerve centers of any active worksite — they are where project planning, safety coordination, and administrative control converge. But in the U.S., it’s not enough for these structures to simply exist; they must comply with OSHA (Occupational Safety and Health Administration) regulations to ensure a safe and legally compliant workspace.

From proper air circulation to electrical grounding and fire prevention, each element of a site office plays a vital role in protecting workers and property. Neglecting OSHA compliance doesn’t just risk penalties — it can jeopardize lives and halt construction progress altogether.

In this guide, we’ll outline the essential requirements for ventilation, electrical safety, and fire protection in construction site offices, along with practical steps to ensure every box on your compliance checklist is ticked.

Understanding OSHA Standards for Site Offices

OSHA’s mission is to ensure safe and healthy working conditions for every worker in the United States. In construction environments, compliance starts with how temporary and semi-permanent structures, such as construction site offices, are designed and maintained.

Key OSHA standards related to these offices include:

- 29 CFR 1926.21 – General safety and health provisions

- 29 CFR 1926.57 – Ventilation requirements

- 29 CFR 1926.403–1926.416 – Electrical systems and grounding

- 29 CFR 1926.150–1926.155 – Fire protection and prevention

These regulations collectively form the framework for designing a safe, compliant, and efficient workspace for administrative and supervisory staff.

Ventilation: Meeting OSHA’s Air Quality Requirements

Good ventilation is not optional—it’s a regulatory and health necessity. OSHA’s 1926.57 standard mandates that every enclosed workspace on a construction site must provide adequate air circulation to protect workers from heat stress, dust, fumes, and toxic vapors.

To meet compliance:

- Ensure at least five to ten air changes per hour, depending on occupancy and climate.

- Position intake and exhaust vents diagonally for optimal air flow.

- Avoid placing HVAC outlets near sources of dust, diesel fumes, or chemical storage.

- Maintain temperature between 68°F and 76°F (20–24°C) for comfort and safety.

Poor ventilation not only reduces worker performance but can also result in OSHA citations and costly downtime. Modular site offices built with insulated panels and integrated HVAC systems provide better air regulation and energy efficiency.

Modern prefab solutions like Construction Site Cabin units are specifically engineered with built-in ventilation channels and sandwich panel insulation, ensuring fresh air circulation even in extreme climates.

Electrical Safety: Powering Your Site the Right Way

Temporary offices rely heavily on electricity — lighting, computers, printers, and HVAC units all require consistent power. According to OSHA 1926.404 and 1926.405, electrical installations at construction sites must follow strict standards for grounding, insulation, and circuit protection.

Here are the essentials:

- Grounding: Every circuit and equipment frame must be grounded to prevent electric shock.

- GFCIs (Ground Fault Circuit Interrupters): Must be installed on all 120-volt single-phase, 15–20 amp receptacles not part of the permanent wiring system.

- Cords & Cables: Only use heavy-duty, outdoor-rated cords; never run cables through doorways or under rugs.

- Panels & Breakers: Keep panels accessible and labeled; never overload circuits.

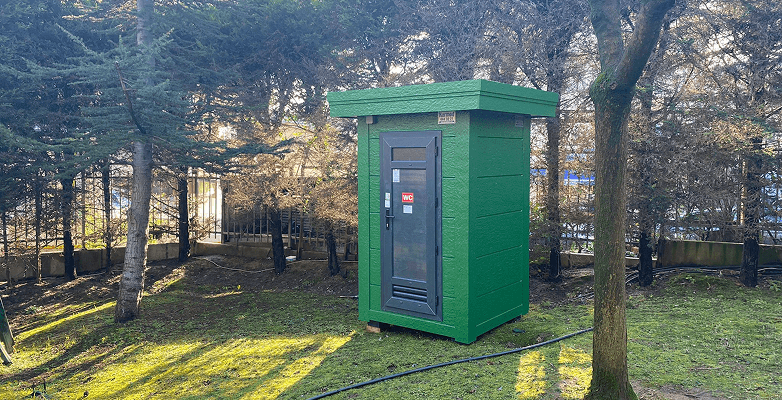

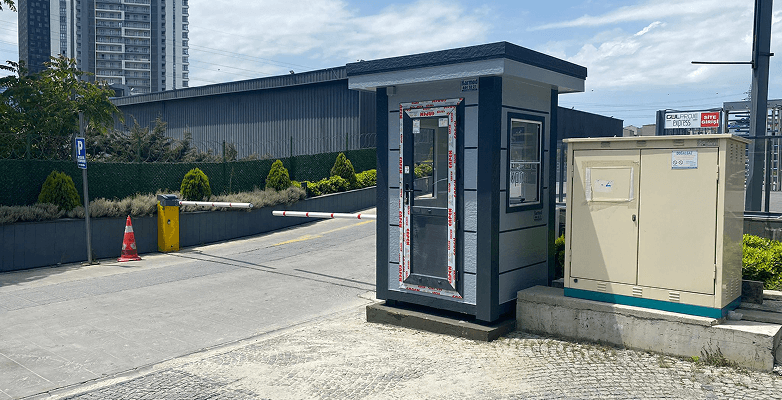

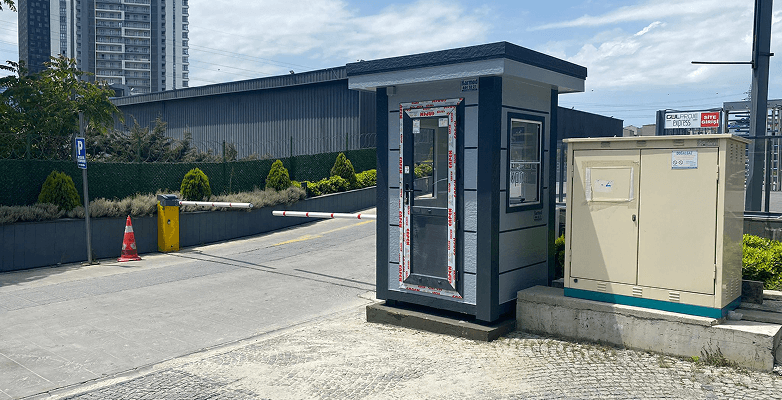

For optimal safety, use prefabricated units pre-equipped with tested electrical layouts. Safety Cabin models from Karmod Cabin incorporate pre-installed conduit systems, factory-tested grounding, and protective switches — drastically reducing the risk of on-site electrical hazards.

Fire Protection: Prevention and Preparedness

Fire risks on construction sites are particularly high due to combustible materials, electrical equipment, and human activity. OSHA’s 1926 Subpart F (Fire Protection and Prevention) sets out detailed rules to minimize these hazards in both permanent and temporary structures.

The main compliance steps include:

- Install Class A, B, and C fire extinguishers within 50 feet of any point in the office.

- Keep two unobstructed exits for offices larger than 500 square feet.

- Store flammable materials in designated safety cabinets.

- Conduct regular inspections and fire drills for on-site staff.

- Maintain emergency lighting and clear signage directing exits.

Construction site offices manufactured by Karmod Cabin are designed with fire-retardant sandwich panels, offering both insulation and structural resistance to flame spread. They can also be equipped with fire detectors and alarm systems as part of the installation package.

For multi-unit setups like break rooms or cafeterias, structures such as Dining Hall Cabin models can be integrated into your safety plan to ensure uniform compliance across the entire worksite.

The OSHA Compliance Checklist

Every construction manager should maintain a written checklist to verify compliance. Below is a simplified version you can adapt for your own site:

Ventilation

- HVAC systems are operational and regularly serviced

- Airflow covers the entire occupied area

- No buildup of dust, fumes, or odors

- Indoor temperature and humidity levels are within OSHA limits

Electrical Safety

- Circuits are grounded and labeled

- Extension cords rated for outdoor use

- GFCIs installed and tested

- Electrical panels unobstructed

Fire Protection

- Fire extinguishers inspected monthly

- Exits clearly marked and illuminated

- No open flames or improper storage of combustibles

- Fire alarms and smoke detectors tested regularly

Keeping this checklist visible inside every construction office not only reinforces compliance but also promotes a safety-first culture among supervisors and workers.

The Role of Karmod Cabin in OSHA-Compliant Design

Karmod Cabin has been supplying prefabricated and modular structures to international construction markets for decades, including the U.S. and North America. Their Construction Site Cabin and Safety Cabin lines are engineered with OSHA’s ventilation, electrical, and fire protection standards in mind.

Each unit is factory-tested for air circulation, wiring integrity, and material durability before shipment. The result is a plug-and-play solution that saves setup time and ensures immediate compliance.

By choosing a certified and fully equipped modular office, companies eliminate many of the risks associated with on-site assembly and inspection delays. Karmod Cabin’s design approach proves that safety, comfort, and operational efficiency can coexist without compromise.

Conclusion: Building Compliance from the Ground Up

An OSHA-compliant construction site office is more than just a regulatory requirement — it’s an investment in worker safety and project reliability. Ventilation, electrical safety, and fire protection aren’t separate concerns; they’re interconnected layers of a single safety ecosystem.

By following OSHA’s clear standards and implementing the right modular solutions, companies can ensure safer, more productive worksites. And with Karmod Cabin’s proven expertise in compliant modular structures, construction managers can focus on building the future — knowing their site offices already meet today’s highest safety expectations.