Hurricane-prone regions across the Gulf and Atlantic coasts face a repeating challenge: protect people, assets, and operations from extreme wind, water, and debris without compromising speed of deployment or budget discipline. Modular cabins that are engineered for wind, uplift, and impact can close this gap—if you know how to specify them correctly. This guide breaks down the essentials: wind load ratings, anchoring systems, materials, and how these choices vary across U.S. climate zones.

Hurricane resistance isn’t a single feature; it’s the result of coordinated decisions across structure, envelope, anchorage, and openings. When owners, engineers, and vendors align on these variables early, cabins install faster, last longer, and pass inspections with fewer surprises.

1) Wind Load Ratings: What They Really Mean

U.S. wind design commonly references ASCE 7 wind maps (risk-based basic wind speeds) and local code adoptions such as the Florida Building Code (FBC) along the High Velocity Hurricane Zone (HVHZ). Practically, you’re juggling three big levers:

- Basic Wind Speed (mph): Typically 115–170+ mph depending on county and exposure (coastal sites trend higher).

- Exposure Category (B, C, D): Terrain roughness—open coast (D) ≫ higher pressures than urban/suburban (B).

- Importance/Risk Category: Essential facilities and critical operations may need greater factors of safety.

Designers translate this into net design pressures (psf) for roof, walls, and components & cladding (C&C). Corners and eaves see the highest suctions; roof geometry matters a lot here.

Specify cabins with stamped calcs for your site—wind speed, exposure, and risk category—rather than generic “hurricane-rated” claims. This forces real engineering on uplift, connections, and glazing, not just heavier panels.

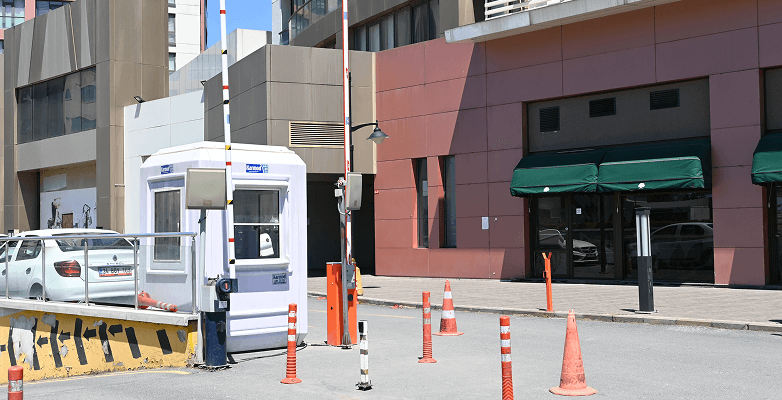

2) Anchoring Systems: Winning (or Losing) Against Uplift

Even the strongest cabin fails if it lifts, slides, or rotates under peak gusts. Your anchoring strategy should address uplift, shear, and overturning together:

- Reinforced Concrete Slab + Mechanical Anchors: Post-installed wedge/adhesive anchors into a designed slab; verify edge distances and embedment for uplift.

- Cast-in Anchors & Base Plates: Best for permanent installs—predictable performance and easier inspection.

- Helical Piles / Ground Screws: Useful where slab isn’t practical; deliver tension resistance in poor soils or flood-prone zones.

- Grade Beams & Tie-Down Frames: Distribute loads along the cabin footprint; pair with straps/tie-downs rated for design uplift.

- Skid-Mounted With Ballast: For temporary deployments; calculate ballast mass for wind + flood scenarios (conservative safety factors).

Connection details matter: hold-down brackets, continuous load paths, and corrosion-resistant fasteners (e.g., hot-dip galvanized, stainless in salt air) keep capacity reliable year after year.

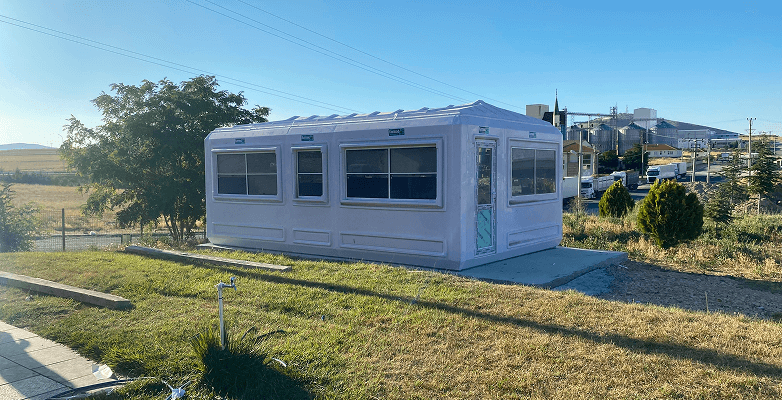

3) Roof Geometry and Why “Crowned” Helps

Aerodynamics influences suction peaks. Low-slope roofs can experience severe edge/corner suctions; hipped/crowned forms often distribute pressures more favorably and shed water faster—vital under driven rain. For coastal sites, consider cabins with crown/hip designs that reduce ponding risk and lower localized C&C demands. Örnek bir seçenek için Crowned Cabins çözümlerini inceleyebilirsiniz.

4) Openings & Impact: Doors, Windows, and Debris

Hurricanes bring flying debris that can breach the envelope and pressurize interiors. Best practices include:

- Impact-rated glazing or shutters where required by local code (e.g., HVHZ zones).

- Multi-point door hardware, outswing doors with continuous hinges, and hurricane-rated frames.

- Sill/threshold details that block driven rain; positive latching so doors don’t blow open.

- Pressure-equalized window systems with proper sealants and backer rods for movement.

Pair glazing choices with interior water management (weep paths, sloped sills) so any intrusion exits without damaging finishes or equipment.

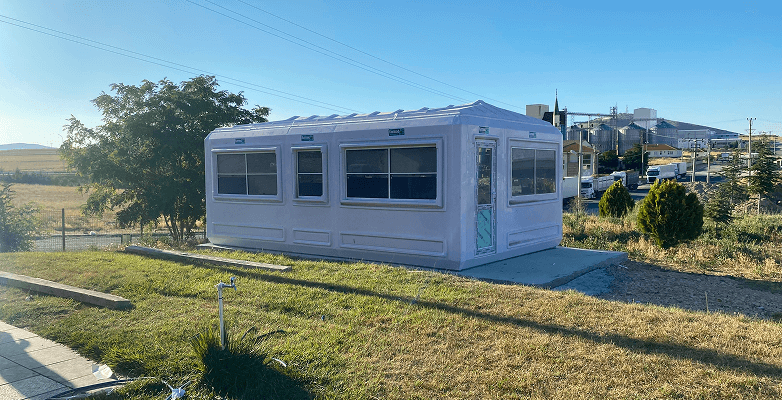

5) Material Comparisons: Steel, Sandwich Panels, and Polyester/GRP

Your material palette affects wind resistance, durability, weight, and set speed.

A) Steel Frame + Sandwich Panel Envelope

A high-performing baseline for hurricane regions: steel framing provides capacity and stiffness, while insulated sandwich panels (outer metal skins + rigid core) deliver structural diaphragm action and thermal performance. Panel seams and corner posts can be engineered as continuous load paths, and panels resist oil-canning with proper gauge and ribbing.

Uygulama örnekleri ve yalıtım avantajları için Sandwich Panel Cabin sayfasına göz atın.

Avantajlar: Excellent strength-to-weight, quick install, good R-value, cleanable surfaces.

Dikkat: Sealant quality and fastener spec (coastal corrosion), edge flashings, and thermal breaks.

B) Polyester/GRP (Fiberglass) Shells

Polyester (GRP/FRP) cabins use molded shells with high corrosion resistance—great for salt air and chemical exposure. With internal frames/ribs, GRP can achieve impressive stiffness, and gelcoat finishes resist UV.

Kıyı iklimlerine uygun seçenekler için Polyester Cabin ürünlerini değerlendirebilirsiniz.

Avantajlar: Corrosion-proof, smooth integrally colored surfaces, lower maintenance.

Dikkat: Engineer connection points for uplift; specify UV-stable resins/gelcoats and bonded inserts for anchors.

C) All-Steel Heavy Gauge

Highest inherent strength, easy to ground for lightning, and rugged for debris impacts with proper skins.

Dikkat: Thermal bridging (solve with insulated assemblies), corrosion protection, and weight/logistics.

Özet: In HVHZ or exposed coastal sites, steel + sandwich panels or engineered GRP shells with reinforced frames usually hit the best cost-to-capacity ratio, provided details (seams, anchors, openings) are designed to the site loads.

6) US Climate Zones: Matching Specs to Region

The U.S. spans IECC climate zones from hot-humid (1A/2A Gulf) to mixed-humid (3A/4A Mid-Atlantic) to marine (4C Pacific). Wind risk, salt corrosion, and thermal needs shift with each zone:

- 1A/2A (Gulf Coast, S. Florida): Highest wind + salt. Prioritize impact openings, crowned/hip roofs, stainless/HDG hardware, elevated slabs, and anti-corrosion coatings.

- 3A/4A (Carolinas, Mid-Atlantic): Significant hurricanes + freeze/thaw. Insulation, air sealing, and robust anchorage; ice-rated HVAC heat strips.

- 5A/6A (Northeast): Lower hurricane frequency but Nor’easters bring wind + driven rain; thermal performance and snow load detailing rise in priority.

- 4C/5C (Pacific Marine): Fewer hurricanes; focus on marine corrosion, seismic anchorage compatibility, and persistent moisture defenses.

Karmod Cabin projelerinde, aynı kabin gövdesi farklı iklim bölgelerine “opsiyon paketleri” ile uyarlanır: coastal-grade fasteners, salt-spray coatings, reinforced tie-downs, impact glazing veya ısıtma/soğutma kapasitesi yükseltmeleri gibi.

7) MEP & Interior: Staying Operational During the Storm

- HVAC sizing: Account for infiltration under pressure; consider variable-speed systems and coastal-grade coils.

- Electrical: Labeled panels, surge protection, and UPS for radios/CCTV; optional generator inlet.

- Water management: Sloped floors at entries, gasketed conduits, raised outlets.

- Acoustics: Wind roar and rain noise fatigue staff—spec insulation and interior finishes that dampen sound.

8) Procurement & Submittals: A Hurricane-Ready Checklist

- Stamped structural calcs (site wind speed, exposure, risk category).

- Anchorage drawings with uplift, shear, overturning calcs (slab, piles, or ground screws).

- Envelope details: panel gauges, core type, corrosion class, sealants, flashing diagrams.

- Openings: impact ratings or shutter specs; multi-point locks; sill/threshold sections.

- Roof geometry: crown/hip option and perimeter edge metal.

- Hardware & coatings: HDG/stainless schedule, paint/coating system data.

- MEP: one-line electrical, HVAC data, condensate routing, generator/UPS provisions.

- QA/QC: factory tests, leak tests, torque specs, and delivery/rigging plan.

- O&M: corrosion maintenance schedule, sealant replacement intervals, anchor inspection guide.

9) Installation & Lifecycle

Plan rigging and set for the windiest shoulder seasons; avoid last-minute installs before a named storm. After commissioning, institute a storm checklist: verify anchor torque, door latch tension, shutter readiness, UPS battery health, and weep/drain clearance. Post-event inspections should log fastener corrosion, sealant cracks, and any glazing damage. Well-detailed cabins routinely deliver 10–20+ years service on the coast with scheduled maintenance.

Why This Matters

Hurricane resistance is about system thinking: structure, anchors, openings, and materials aligned to your wind map and exposure. Cutting corners on any single piece can compromise the whole cabin under peak gusts. With a vendor ecosystem that embraces stamped engineering, you buy certainty—not just metal and panels.

Karmod Cabin, global modüler üretim tecrübesiyle; coastal-grade malzeme paketleri, sahaya özel ankraj çözümleri ve mühendislik dokümantasyonu ile ABD iklim bölgelerinde tekrarlanabilir kalite sunar. Tasarımlar, rüzgâr yükü ve korozyon gerekliliklerine göre özelleştirilebilir.