US projects—from schools and hospitals to logistics yards and corporate campuses—are under pressure to deliver more space, faster, with tighter budgets and fewer disruptions. In this context, portable cabins (factory-built, modular units delivered ready to commission) are increasingly evaluated alongside traditional construction (stick-built or site-cast methods). The question is no longer “Can modular work?” but “Where does modular outperform—and by how much?”

Portable cabins compress schedules, de-risk budgets, and keep sites productive by moving most of the work off-site into controlled factory conditions. When owners map total cost of ownership (TCO) and delivery risk—not just headline CAPEX—portable cabins often create the shortest, safest path to usable space.

1) Cost: Beyond the Sticker Price

Traditional projects frequently start with competitive bids that look lean, but soft costs and downstream changes inflate the final number. Portable cabins rebalance the equation:

- Predictable CAPEX: Factory repeatability reduces waste and rework. Scoped options (windows, HVAC tonnage, interior fit) are priced in advance instead of piling up as change orders.

- Lower Soft Costs: Less on-site labor, fewer inspections stretched over months, reduced general conditions (site supervision, temporary utilities, fencing, security).

- Financing & Cash Flow: Shorter build times mean earlier occupancy and revenue; the carrying cost of capital drops.

- Lifecycle & Reuse: If needs change, units can be relocated, reconfigured, or resold—something traditional structures rarely allow without major loss.

A practical way to compare is to model $/usable week rather than $/sf. If a site-built office costs less per square foot but arrives 6–9 months later, the “cost of delay” (lost productivity, rentals, inflation) can eclipse any nominal savings.

2) Time: Schedule Compression You Can Bank On

Portable cabins are built in parallel with site prep. While foundations, utilities, and permits progress, the unit is fabricated in the factory. This parallelism eliminates weather downtime, labor bottlenecks, and inspection sequencing issues that regularly push traditional schedules to the right.

Typical gains include:

- 30–60% faster from NTP to occupancy for like-for-like scope

- Fewer critical path items (no multi-trade stacking or long cure times)

- Factory acceptance testing before delivery, so on-site commissioning is days—not weeks

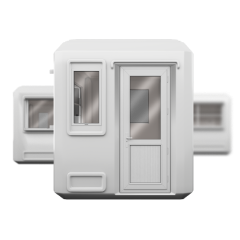

For rapid field offices and project command posts, modular site offices such as Construction Site Cabin arrive pre-wired and insulated, with device cutouts ready for access control and CCTV—dramatically reducing set-up time.

3) Flexibility: Build What You Need, Then Move It

Traditional buildings are fixed assets. Portable cabins are operational assets: scale up for peak programs, scale down when the work is done, redeploy to a new campus or yard.

- Scalability: Add a second unit for seasonal peaks; stack or line units for larger footprints.

- Relocation: Move with the project phases rather than paying for redundant buildings.

- Reconfiguration: Swap windows/doors, counters, and equipment rails without starting from scratch.

- Temporary-to-Permanent: Start as a temporary asset and convert to longer-term use with upgraded anchoring, ramps, and interior specs.

For event seasons, pop-up operations, or multi-site logistics, mobile formats like Mobo Cabin provide the footprint, power, lighting, and climate control of a small building—with the agility of a fleet asset.

4) Quality and Performance: Factory Repeatability vs. Field Variability

Portable cabins are produced under controlled conditions with consistent materials, jigs, and QA. That yields straighter walls, tighter envelopes, and cleaner electrical runs than many field-built equivalents exposed to rain, wind, and trade stacking.

Key performance wins:

- Envelope & Insulation: High R-values and continuous insulation details are easier to achieve in the factory; insulated panels help maintain interior comfort and cut energy spend.

- Moisture Control: Materials stay dry during assembly; seams and penetrations are sealed under cover.

- Fit & Finish: Repetitive assembly improves ergonomics—worktops, monitors, and cable management land exactly where they should.

- Testing: Electrical, HVAC, and device cutouts are powered and labeled before shipment, shortening punch lists on site.

If energy efficiency and cleanability are priorities, panelized envelopes like those used in Sandwich Panel Cabinoffer a compelling balance of thermal performance, speed, and durability.

5) Risk: Fewer Surprises, Better Outcomes

Schedule slip, labor shortages, and weather are the top three causes of overruns in traditional projects. Portable cabins shift risk off the site:

- Weather Immunity: Most assembly happens indoors; delivery becomes a logistics window rather than a multi-month exposure to storms.

- Labor Certainty: Factory crews are stable and specialized; fewer subcontractor dependencies.

- Inspection Efficiency: Fewer on-site inspections, more standardized documentation, and shorter durations for AHJ sign-offs.

- Safety: Less time at risk in live environments (busy campuses, operating plants, public streets).

Modular methods don’t just save time—they cut the number of things that can go wrong. For owners managing critical operations, that reliability is often worth more than small unit-cost deltas.

6) Compliance, Codes, and Anchoring

Both approaches must comply with building, electrical, mechanical, energy, and accessibility codes. Portable cabins typically present simpler pathways for temporary or semi-permanent approvals:

- Anchoring & Foundations: Slabs with mechanical anchors, cast-in plates, helical piles, or ballast frames depending on wind and soil.

- ADA: Door clear widths, ramp slopes, thresholds, and maneuvering clearances are standardized and documented.

- Energy & HVAC: Right-sized capacity with factory-documented performance data and labeled electrical one-lines.

- Wind/Snow/Seismic: Stamped calculations tailored to the jurisdiction, often faster to review due to standardized details.

Traditional buildings shine for custom architecture, multi-story structures, and highly specialized occupancies; however, for single-story operational spaces, portable cabins often navigate approvals more quickly.

7) Site Impact: Keep the Campus Running

Traditional builds consume staging space, restrict parking, generate noise/dust, and require long safety perimeters. Portable cabins minimize site disruption:

- Shorter mobilization and faster demobilization

- Smaller crews and equipment footprints

- Fewer deliveries and less waste on campus

- Weekday-friendly commissioning windows that don’t derail operations

For hospitals, schools, and live industrial plants, this low-impact profile can be the deciding factor.

8) TCO Model: A Simple Comparison Framework

When evaluating options, consider:

- CAPEX: Unit price + options + delivery + set + anchoring + utilities

- Time-to-Use: Revenue/service weeks gained or rentals avoided

- OPEX: Energy, cleaning, planned maintenance (filters, seals, coatings)

- Flexibility Value: Relocation, resale, or repurpose credits

- Risk Premium: Probability-weighted cost of delay and overruns

Owners who quantify time value and flexibility credits often find portable cabins win on TCO even when per-square-foot CAPEX is similar.

9) Where Traditional Still Wins

- Iconic architecture with bespoke forms and finishes

- Multi-story structures or specialized labs with heavy MEP

- Very long lifespans where resale/relocation isn’t relevant

- Zoning overlays that mandate masonry or specific aesthetics

The best strategy is not either/or but fit-for-purpose—use traditional where permanence and customization matter most, and deploy portable cabins for operational speed, scalability, and risk control.

The Vendor Factor

Transparent manufacturers publish wind/snow/seismic ratings, insulation values, electrical one-lines, and option packs up front. That clarity shortens submittals and reduces friction with authorities having jurisdiction. Karmod Cabin is frequently chosen in US projects for exactly this predictability—factory testing, clean documentation, and configurable layouts that integrate access control, CCTV, radios, and IT neatly.

For multi-site rollouts, Karmod Cabin can standardize a base spec (sizes, panels, HVAC, device rails) and layer options (extra glazing, ballistic packages, higher wind ratings) so procurement stays simple while sites get what they need.

Conclusion: Speed, Certainty, and Optionality

Portable cabins and traditional construction both have roles in the US market. If the objective is fast, flexible, and cost-stable space that keeps operations moving, modular wins decisively in most single-story, small-to-medium footprints. If the objective is bespoke form, long permanence, or multi-story complexity, traditional is the right tool.

The highest-ROI path is to measure value in weeks saved, risks avoided, and options preserved—not just dollars per square foot. Viewed through that lens, portable cabins are not a compromise; they are a smarter operating model for delivering space at the speed of business.