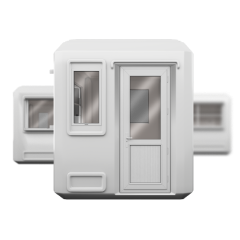

In the U.S., the term guard shack (also called guard booth, guard house, security kiosk, or gatehouse) describes a compact, enclosed workspace positioned at an entry or high-risk zone where trained personnel control access, observe activity, and coordinate responses. More than a hut with a window, a modern guard shack is a mini command center that blends physical protection, visibility, and connected technology to keep people, property, and operations safe.

A guard shack is not just a shelter — it is the physical control point where your safety policies become real-world actions. When it’s designed properly, it speeds up entry, reduces errors, and provides a safer, more professional first touchpoint for visitors, drivers, and contractors.

Terminology, clarified

- Guard shack / guard booth / guard house: Interchangeable in most commercial settings; “booth” is common in parking and venues, “house” near campuses or residential communities.

- Security kiosk: Smaller footprint, typically for ticketing or visitor check-in.

- Armored / bullet-resistant booth: A guard shack built with ballistic steel and laminated glazing to NIJ/UL levels.

- Portable vs. permanent: Portable units are skid- or trailer-mounted; permanent units are anchored on a concrete pad with utility connections.

Where and why organizations use them

- Parking facilities & garages: Credential checks, ticket validation, cash-handling oversight, LPR camera integration.

- Event venues & stadiums: Crowd flow, VIP/staff lanes, emergency messaging, bag-check coordination.

- Logistics & distribution yards: Gate-in/gate-out time stamps, seal verification, OSHA checklists, after-hours control.

- Construction sites: Worker badging, tool gate control, safety briefings, delivery scheduling.

- Banks & corporate campuses: Visitor management, lobby pre-screening, deterrence against theft or intrusion.

- Healthcare & education: Wayfinding for visitors, controlled deliveries, lockdown coordination when needed.

Core functions of a modern guard shack

- Access control hub: Scan IDs, verify work orders, validate tickets, and issue temporary credentials.

- Observation & deterrence: Elevated sightlines and lighting reduce blind spots and discourage misconduct.

- Communications node: Radios, intercoms, and VoIP tie guards to dispatch, facilities, and law enforcement.

- Incident command: Space for SOP binders, first-aid kits, AED, spill kits, and emergency checklists.

- Comfort & endurance: HVAC, insulation, and ergonomic layouts sustain alertness on long shifts.

Selecting the wrong spec usually costs more in downtime, rework, and risk than whatever “savings” you thought you were getting.

Architecture & materials that matter

- Structure: Welded steel frames or engineered GRP/FRP shells; look for corrosion protection and sealed seams.

- Envelope & insulation: Sandwich panels with foam cores improve thermal performance and speed installation.

- Glazing: Tempered or laminated; optional ballistic levels; low-E or tint to cut glare and heat.

- Doors & hardware: Self-closers, panic hardware, ADA-friendly clear widths, and weatherproof thresholds.

- Flooring: Anti-fatigue, non-slip surfaces with cable pass-throughs for a neat console area.

- Electrical & low-voltage: Dedicated circuits for HVAC and monitors; raceways for cameras, readers, and sensors.

- Lighting: Dimmable interior task lighting; exterior LEDs for apron illumination without glare.

Tip: For energy efficiency and easy cleaning in semi-permanent locations, sandwich-panel designs like those used in Sandwich Panel Cabin are a strong baseline.

Climate control & ergonomics

Guards perform better when they are comfortable and can see clearly. Prioritize:

- Right-sized HVAC (BTU/ton matched to volume and climate zone), fresh-air intake, and filtration.

- Solar and wind exposure planning (overhangs, films, orientation) to maintain stable temperatures.

- Sightlines: 360° wraparound windows, narrow mullions, and strategic booth placement (slight elevation or diagonal to flows).

- Work ergonomics: Standing-height counters with stool options, monitor arms, document trays, and cable management.

- Acoustics: Insulation that blocks road noise to reduce fatigue and improve radio clarity.

For valet, parking, and drop-off operations that need tight footprints and fast setup, see Valet Shed for form factors optimized around window placement and curb-side interactions.

Technology stack to plan up front

- Access systems: Proximity/RFID readers, barcode/QR, PIN pads; integrate with visitor management software.

- Vehicle automation: LPR cameras tied to barrier arms and pre-approved lists.

- Video & analytics: VMS with smart alerts (loitering, tailgating); privacy masking for compliance.

- Comms: IP intercoms, radios, PA for mass notification; panic buttons routed to dispatch.

- Networking & power: PoE switches, UPS backup, surge protection, and labeled panels for fast maintenance.

- Data & audit: Time-stamped gate logs and integrations with WMS/yard management systems.

Safety, codes, and compliance

While requirements vary by city and state, plan for:

- ADA considerations: Clear approach, threshold ≤ 1/2 in, operable hardware, interior turning radius if public-facing.

- Electrical safety: GFCI where needed, grounded panels, neat labeling, and clearance.

- Fire & life safety: Proper extinguisher class and mounting, illuminated exits for larger footprints.

- Wind/snow/seismic loads: Ensure structural calculations match local code for the installed location.

- Optional ballistic protection: NIJ/UL ratings appropriate to your risk profile (banks, critical facilities).

Sizing & layout: what fits where

Common footprints and staffing patterns (approximate interior dimensions):

- 6'×8' (1–2 staff): Parking gates, light venues, kiosks.

- 8'×10' (2 staff + visitor lane): Busy garages, school entries, mid-size event gates.

- 8'×12' or 10'×12' (2–3 staff): Logistics yards, stadiums, mixed vehicle/pedestrian lanes.

Layout must reserve wall space for windows and consoles; avoid placing tall equipment where it blocks external views. Provide a small equipment closet or overhead cabinet for routers, NVRs, and spares.

Mobility, foundations, and utilities

- Portable (skid/trailer): Deploy fast; ideal for seasonal events and temporary checkpoints.

- Permanent (pad-mounted): Cleaner cable runs, better aesthetics, easier ADA ramps, and higher wind ratings.

- Utility planning: Trench or surface-run for power/data; protect with conduit; separate high/low voltage.

- Drainage & snow: Keep thresholds above grade; add mats and canopy overhangs at the door.

- Permits: Confirm local zoning and electrical permits before delivery to avoid delays and rework.

For job sites that evolve over months, a ruggedized option like Construction Site Cabin provides a durable envelope that can be re-deployed as phases change.

Deployment playbook (from site survey to “go live”)

- Risk & throughput assessment: Peak vehicles/hour, pedestrian surges, threat profile, staffing model.

- Site survey: Turning radii, approach lanes, utilities, and camera sightlines.

- Spec sheet & drawings: Floor plan, elevations, loads, electrical one-line, device schedule.

- Procurement: RFP with mandatory/optional items, submittals for materials and certifications.

- Pad & trenching: Coordinate slab, anchors, conduits, and drainage.

- Factory acceptance (optional): Power-up and label check before shipping.

- Delivery & set: Crane or forklift plan; safety perimeter and traffic reroutes.

- Commissioning: Power, network, device tests; SOPs posted; staff training.

- Handover: As-builts, warranties, maintenance schedule, spare parts kit.

Maintenance & total cost of ownership (TCO)

- Monthly: Clean filters, test radios and intercoms, check door closers and seals.

- Quarterly: Inspect glazing, re-caulk seams, verify UPS and camera health, back up configurations.

- Annually: HVAC service, repaint touch points, re-level anchors, full electrical safety check.

Budget beyond the initial purchase: shipping, pad, crane, trenching, commissioning, spares, and periodic upgrades (cameras, NVR storage). Tracking mean time to repair (MTTR) and uptime will show the value of quality manufacturing over the lowest bid.

Sustainability & aesthetics

Energy-efficient insulation, LED lighting, low-VOC finishes, and optional solar assist reduce operating costs. Thoughtful exterior colors, logo panels, and canopy lines help booths blend with campus or brand identity—useful for retail, higher-ed, and corporate campuses that value visual continuity.

How Karmod Cabin fits in

Manufacturers like Karmod Cabin deliver modular booths that arrive pre-wired and ready to commission, with configurable windows, door swing, HVAC tonnage, and device cutouts to suit parking lots, campuses, and high-throughput gates. Their global experience translates to predictable lead times and factory testing that shortens onsite schedules without compromising quality.

If you are standardizing across multiple sites, Karmod Cabin can align a base spec (sizes, panels, power, device rails) and then offer option packs (ballistic glazing, extended HVAC, extra windows) so procurement stays simple while each location gets exactly what it needs.

RFP checklist you can copy

- Footprint and height; occupancy count

- Wall type and insulation R-value; roof and floor specs

- Window size, glazing type (standard or ballistic), mullion widths

- Door swing, ADA clear width, hardware

- HVAC capacity, filtration, fresh-air

- Electrical panel size, outlets, raceways, UPS

- Tech devices and mounts: LPR, readers, intercoms, cameras, monitors

- Lighting (interior/exterior), egress, signage

- Wind/snow/seismic ratings; anchoring method

- Finish, colors, branding, warranty, delivery and set plan