Feeding large crews safely and efficiently is one of the most overlooked yet critical aspects of managing a construction site. In the United States, where projects often operate under strict labor laws and demanding timelines, a well-designed dining hall cabin is not just a convenience—it’s a necessity. These modular facilities ensure that workers have access to clean, safe, and comfortable eating spaces, directly contributing to morale, productivity, and compliance with health standards.

Why Dining Facilities Matter on Construction Sites

Construction sites are fast-paced, high-stress environments where every minute counts. Providing structured dining areas helps prevent accidents related to fatigue, dehydration, or improper eating conditions. Moreover, federal guidelines such as OSHA’s sanitation standards require employers to maintain designated areas for meal consumption away from hazardous materials.

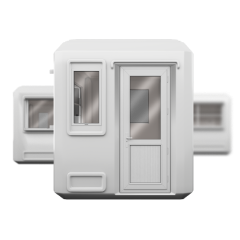

Dining hall cabins bridge this gap perfectly. They offer a cost-effective, modular solution that can be installed quickly, relocated easily, and maintained with minimal disruption. Dining Hall Cabin models are specifically engineered to accommodate varying workforce sizes, ensuring compliance while improving worker well-being.

Food Safety Standards and Best Practices in the US

Food safety in temporary dining setups goes beyond serving fresh meals. It involves managing hygiene, ventilation, temperature, and waste control inside enclosed modular units.

According to the U.S. Food and Drug Administration (FDA), the main risks on construction dining sites include improper food storage, cross-contamination, and temperature abuse. A properly equipped dining hall cabin should therefore include:

- Insulated walls and temperature-controlled interiors to preserve meal quality.

- Non-porous, easy-to-clean surfaces to prevent bacterial buildup.

- Segregated areas for food preparation and consumption.

- Ventilation systems that control humidity and odor.

By integrating these features, contractors can align with both FDA and OSHA requirements, reducing the risk of violations or foodborne illnesses.

Properly designed modular dining spaces not only protect workers but also help companies meet public health and safety expectations without excessive cost.

Waste Management: Efficiency and Environmental Compliance

Waste management on a construction site often extends beyond building debris—food waste can quickly become a logistical and hygiene problem. Inadequate disposal methods attract pests, generate odors, and create health hazards.

Modern modular dining cabins are designed to support efficient waste collection systems, separating organic waste from recyclables. Incorporating solutions such as compact waste stations, sealed bins, and designated cleaning zones helps maintain a sanitary environment.

For example, pairing dining facilities with a nearby Safety Cabin ensures that hygiene and waste protocols are managed efficiently by dedicated personnel. Some large projects also integrate a Bread Buffet or snack station module, allowing waste segregation at the source and reducing cleanup time.

Environmentally conscious construction companies in the U.S. are also adopting waste-to-energy programs, turning food waste into biogas or compost. Modular cabins can be easily adapted to support these sustainability goals.

Capacity Planning: Feeding Large Crews Efficiently

A key challenge on construction sites is scaling dining capacity according to project size and crew turnover. A site with 50 workers may require a single 30-square-meter cabin, while a large-scale infrastructure project might need several interconnected modules.

Efficient capacity planning ensures that meal service remains smooth even during peak hours, avoiding downtime or overcrowding.

When planning, managers should consider:

- Crew Size: 1.2 square meters per person is the standard for comfortable dining space.

- Shift Schedules: Staggered lunch breaks help optimize limited capacity.

- Kitchen-to-Table Flow: Food preparation and service areas must minimize cross-traffic.

- Accessibility: Compliance with ADA (Americans with Disabilities Act) ensures inclusivity for all workers.

Well-planned dining areas not only streamline operations but also demonstrate an employer’s commitment to worker welfare — a factor increasingly valued in project tenders across the U.S. construction industry.

Design and Material Considerations for Dining Hall Cabins

The material quality of dining cabins directly impacts hygiene, durability, and long-term ROI. Construction Site Cabin models made from steel-reinforced frames and sandwich panels are ideal for American climates, offering insulation and structural integrity.

Interior design also plays a major role. Smooth wall surfaces, anti-slip floors, and pre-installed HVAC systems create a comfortable dining environment regardless of season. Natural lighting and large windows can enhance the sense of space, which is particularly important for workers spending long hours outdoors.

Karmod Cabin’s modular systems utilize high-grade sandwich panel materials that combine hygiene with quick assembly—making them a top choice for both temporary and semi-permanent site facilities.

Karmod Cabin has built a global reputation for providing high-quality modular structures that meet international safety and comfort standards. Their dining hall solutions are specifically designed to accommodate U.S. site conditions — from humid southern states to cold northern environments.

The company’s cabins are pre-fabricated under strict quality control, ensuring each unit is compliant with food safety and building codes. Their modular dining units can be expanded, connected, or relocated as project needs evolve, reducing waste and operational costs.

By integrating technology, ergonomics, and hygiene, Karmod Cabin continues to help American contractors create safer and more efficient work environments — one cabin at a time.

In today’s construction landscape, providing a clean, safe, and efficient dining space is more than a regulatory requirement — it’s a productivity strategy. Dining hall cabins offer a modular, cost-effective way to meet these needs, supporting worker health, reducing waste, and improving site logistics.

As U.S. construction projects become more complex, investing in smart modular dining facilities will continue to be a defining factor in project success.

To explore durable and hygienic solutions that meet your team’s needs, visit Karmod Cabin and discover how modular innovation can redefine the way your site operates.